As expressed in our Manifesto, Nova Somor srl also wants to have a cultural role, aiming to foster people’s change and awareness for a world where less energy is wasted. It therefore seems appropriate to explain the principles of our technology in as simple and comprehensible manner as possible, both for our customers, and for anyone who desires knowledge and understanding.

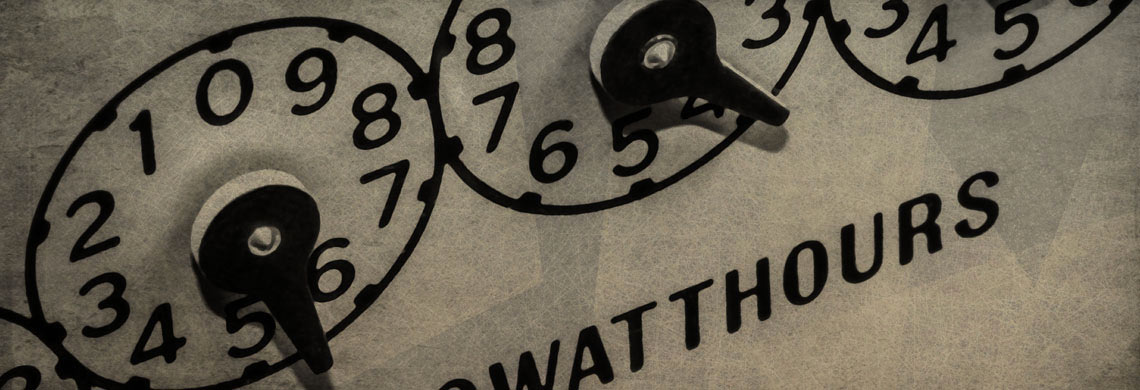

Over the years we have lost sight of the value of energy, which replaces a great deal of physical work, and of how difficult it is to produce, especially electricity. We take it for granted and continuously design new products and machines that do not consider this difficulty and therefore are wasteful. In order to fully understand what we mean in the case of electricity, we have to imagine the equivalence of Wh (Watt per hour) converted into useful work. One Wh is equivalent to the effort required to raise 5 heavy bags, 25 kg each, upstairs, or to raise 360 kg for a metre. So this famous Kilowatt per hour (1000 Wh) is equivalent to raising 360 tons of weight for a metre. And we pay about 20 euro cents! Just recharging the battery of our mobile phone takes more than 7 Wh. If we were to “physically” produce this energy, we would have to take up one floor, on our shoulders, 35 bags of 25 kg each time we want to recharge our phone!

That’s why our products are not powered by electricity and do not have any electrical component “on board”. Electricity would make our lives easier, but this way we would fall into a never-ending vicious circle, one that multiplies entropic steps and therefore waste. Instead Nova Somor srl builds machines that do not consume any fossil fuels or electricity during use and we think we give a positive contribution to the change which is taking place. It is a concrete example of bio-economy, namely that science developed in the 70s by Nicholas Georgescu Roegen that tries to leave something additional to future generations and to immediately reduce emissions of greenhouse gases.

ITA

ITA ENG

ENG FRA

FRA ESP

ESP POR

POR